home

needs

local resources

comfort

safety & health

contact

reports

Type / Amount

This is one of the largest and probably most demanding functions of a designer whenever a drastically new product is being developed for introduction into the market. Since we are concerned with a cook stove, and since food is now being cooked and eaten, we have here to contend with two distinct types of problems. One is about the food itself and the other concerns the competition from the existing technology.

The customer profile

can be depicted according to the diagram shown in figure 1.

The type of food eaten by people comes in a bewildering variety.

The number of cookbooks one encounters in an average book store bears

abundant testimony to this observation. This is only the documented part of

the folklore associated with food and cooking. There maybe two or even five

times this variety undocumented. Does this mean that we have to have a

design for every dish? The answer is a simple no. Let us examine the cooking

evidence from around the world. The Southern Karnataka's ``ragi mudde'',

East Africa's ``ugali'', and the Sahelian ``tuo'' are close first cousins

involving the cooking of a millet flour in water the final product being a

thick paste. ``Roti'' made from diverse grain flours in many parts of India

and the Mexican tortillas are traditional bread forms and their preparation

procedure is roughly the same. Rice knows no boundaries - it is eaten

everywhere. Vegetables, fish and meat come in diverse forms but are treated

in more or less similar manner around the five continents. Believe it or

not, with a bit of ingenuity, the thousands of dishes of this world can be

and are being cooked on the much maligned open fire.

Maybe the advanced technologies do not have this property of the open fire. That is not true either. In Western Europe nobody would suggest that the British, French and Italian cooking are alike - in fact each is quite distinct. But however they all happily cook on gas/electric stoves/ovens. The difference in various foods is mainly one of spicing and the final consistency. Instead of emphasizing the differences we could start looking at the similarities.

Cooking categories

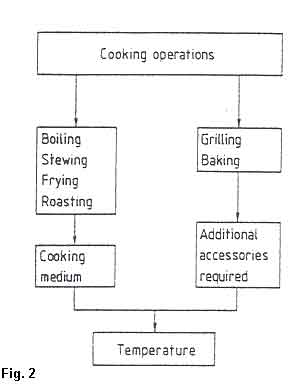

Such an approach will lead to six principal cooking operations shown

diagrammatically in figure 2 .

Thus the design implications of these are that the cooking media can be different

and the temperature requirements will differ. For baking one requires special

accessories like a hot box or a boiler for steam baking. For grilling a grate-like

thing would be needed. These accessories are for people who can afford and fancy

such food.

We shall now, following Verhaart(1983), provide a brief description about these different cooking processes. Boiling is probably one of the most important cooking process. For example cooking rice or a stew involves bringing a mixture of water and the food concerned to the boiling temperature of water and maintaining the mixture at that temperature for a specified period of time depending on the nature of food being cooked. For food like potatoes or other tubers, cooking involves bringing the mixture of water and these to boiling and holding them at the boiling temperature till such time as the centre of the tuber attains the boiling temperature. In cases like dried pulses and beans, which are mostly small particles, cooking involves not only the whole particle attaining the boiling temperature, but also moisture has to migrate into the interior of the particle before any chemical reaction can occur. It appears that the process of moisture migration is extremely slow and the cooking times and by the same token the energy consumption are quite large. However if one adopts the expediency of soaking these substances for a length of time before cooking, energy and time for cooking can be saved. Frying in all its variations is a non-uniform temperature process. The temperature of pan and the cooking medium are well above the boiling temperature of water, probably around 180 °C. However the input food loses moisture by evaporation while heat penetrates into the interior. Depending on the power per unit exposed area and thermal properties of the food, as the outer layers lose moisture, the temperature of its outer surface rises and some thermal decomposition occurs. A crust is formed. This crust is an essential part of most fried foods. Frying in general is a high power input process and as will be shown later is also a high energy consuming process.

Baking is a process in which heat is transferred by radiation from the oven walls to the food. Essentially the energy required for this type of cooking is just the amount of heat required to raise the temperature of the food to the boiling temperature of water with a little extra for browning the crust. In an average oven the heat is supplied at temperatures between 180 and 250 °C depending on the type of food being prepared. Again this is a highly energy consuming process due to the fact that the ovens on the average have to cater for differing quantities of food at different times and an unusually large amount of energy is required to preheat the oven. This is particularly so for a class of bread baked in north-west India, Pakistan, Afghanistan and many middle-eastern countries. This bread, known as "nan" in India and Pakistan, is traditionally baked in clay ovens and are reputed to be tremendously energy inefficient.

Grilling is again a process where heat is transferred by radiation. The food again needs to be raised essentially to the boiling temperature of water. Crust formation is an essential need here as well. In this process lot of heat is radiated away uselessly and thus consumes a lot of energy.

Quantity of food

The next ``box'' in the customer profile of figure 1 is the quantity of food cooked. This is simply obtained by knowing the family size. One way of doing this is to carry out a sample survey of the prospective clientele. A second approach is to take a look at the latest census data for the region concerned. A more rewarding approach is to look at the pans used by the prospective clientele for the stove. This approach kills two birds with one shot as it were. The shape and size of pans are important inputs to design from both process and mechanical considerations. The size of the pan is a very good indicator of the quantity of the food cooked. From time immemorial earthenware pots have been used for cooking. Well to do people replaced these with bronze and cast iron pans. In modern times pans are invariably made out of aluminium, stainless steel and cast iron.

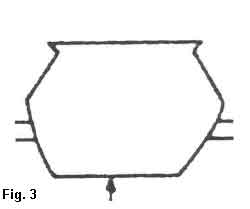

The figures 1, 2 and 3 shows three generic types of pans - one from Southern Karnataka

(with a broad base and conical top, fig. 1), the popular flat bottomed pressed aluminium pan used

almost everywhere (fig. 2) and one from the Sahel (spherical bottomed

cast aluminium, fig.3).